Products

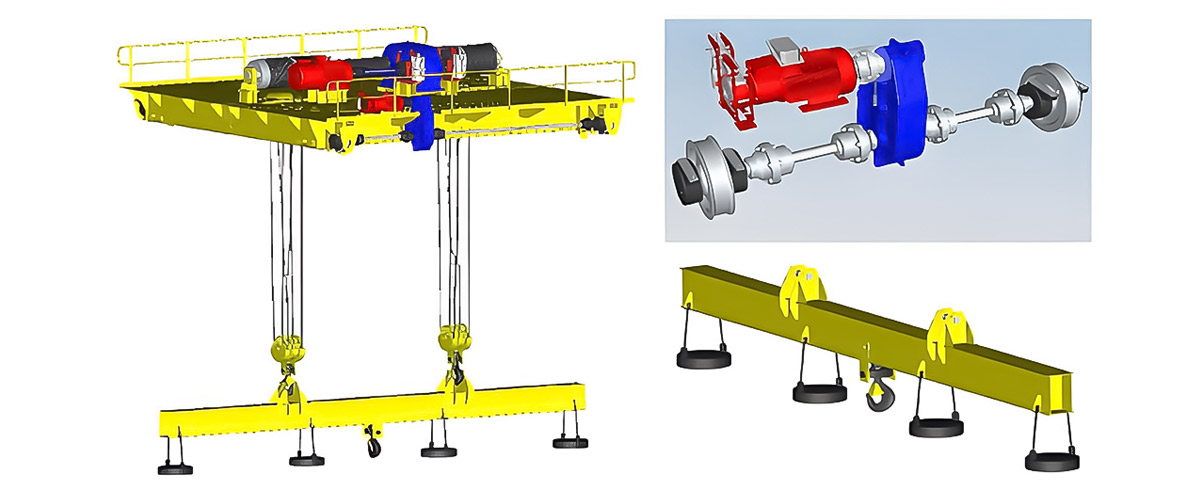

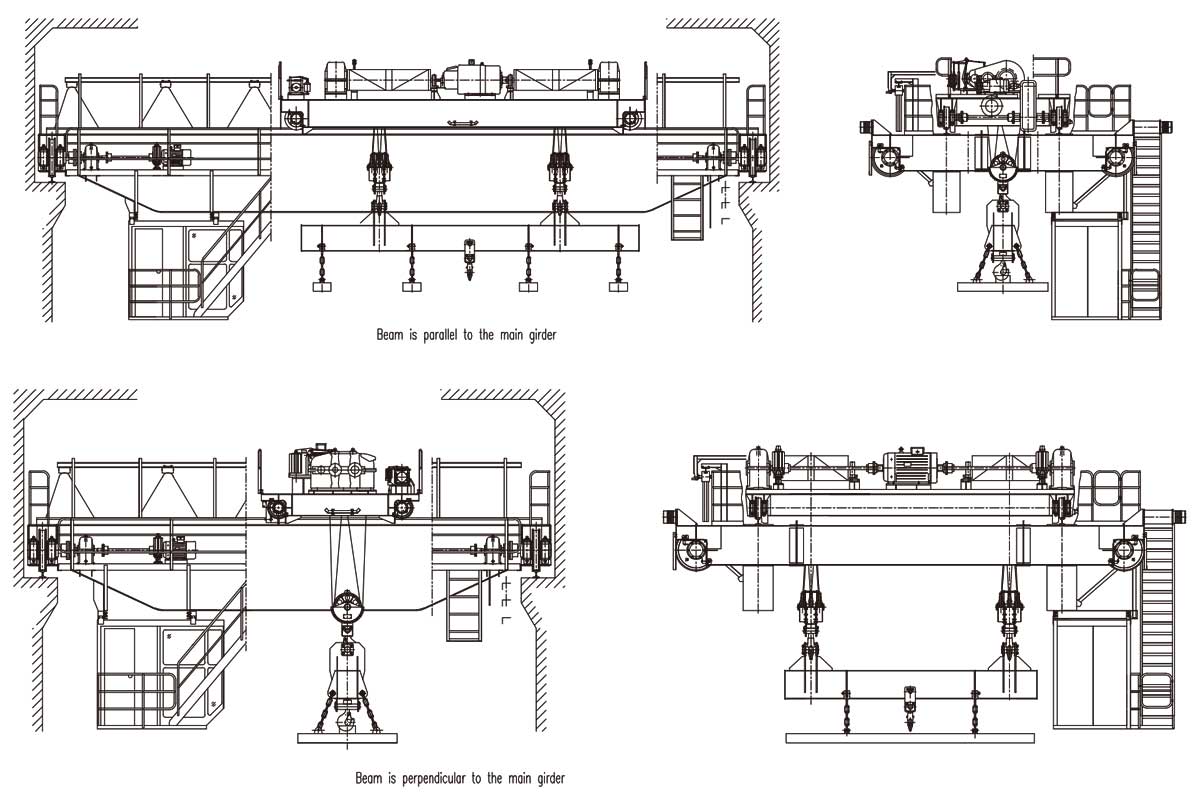

Electromagnetic beam overhead crane is an efficient lifting equipment specially for handling and stacking metal materials. According to the layout of the main beam, there are four types: parallel to main girder, vertical to main girder, upper rotation beam type and lower rotation beam type.

Electromagnetic beam overhead crane is an efficient lifting equipment specially for handling and stacking metal materials. According to the layout of the main beam, there are four types: parallel to main girder, vertical to main girder, upper rotation beam type and lower rotation beam type. These four types are different in structural design, operation mode and applicable working sites.

Steel manufacturing and processing

In steel mills and steel rolling mills, electromagnetic beam overhead crane could efficiently carry metal materials such as steel plates and billets. Electromagnetic hanging beams can firmly adsorb metals of various shapes, improve operational efficiency and reduce manual intervention.

Machinery manufacturing workshop

For machinery manufacturing plants, it is to carry and assemble large metal parts such as machine tool beds and engine components. Its precise control capability ensures the safe handling and precise positioning of complex workpieces.

Automobile manufacturing factory

During the automobile manufacturing process, it is capable of carrying heavy metal components such as vehicle body parts and engines. The electromagnetic hanging beam design improves the safety and efficiency of the handling process and reduces the risk of damage to vulnerable parts.

Scrap metal recycling station

In the scrap metal recycling station, it is to sort and transport scrap metals such as scrap iron, scrap steel, etc. Electromagnetic hanging beams can quickly adsorb and transport large amounts of scrap metal, greatly improving processing efficiency and safety.

Strong electromagnetic adsorption capability

The electromagnetic beam bridge crane has the powerful electromagnets that can firmly adsorb metal materials of various shapes and sizes, whether they are steel plates, billets or other heavy-duty metal parts. This adsorption method not only improves handling efficiency, but also reduces the manual intervention, ensuring the safety and stability.

Flexible operating system

With advanced control systems, including a frequency converter speed control system and a PLC (programmable logic controller), it supports fine-tuning operations to ensure accurate positioning and safe hoisting in a limited space. The wireless remote control and cab operation modes provide greater flexibility to adapt to different operating needs.

Multifunctional hanging beam design

The electromagnetic hanging beam can be adjusted according to different operating needs, such as changing the number, position, or magnetic field strength of the electromagnet. The upper and lower rotary hanging beam designs provide greater operational flexibility, allowing bridge crane to handle material on a larger scale, adapting to complex workpiece shapes and sizes.

| Electromagnetic Overhead Crane With Carrier-beam | ||||||||||||||||||||||

| Capacity(ton) | 15 | 20 | 32 | 20+20 | ||||||||||||||||||

| Span (m) | 22.5 | 25.5 | 28.5 | 31.5 | 34.5 | 22.5 | 25.5 | 28.5 | 31.5 | 34.5 | 22.5 | 25.5 | 28.5 | 31.5 | 34.5 | 22.5 | 25.5 | 28.5 | 31.5 | 34.5 | ||

| Lifting Height (m) | 16 | 16 | 16 | 16 | ||||||||||||||||||

| Working Duty | A6 | A6 | A6 | A6 | ||||||||||||||||||

| Speed | Lifting Speed | m/min | 13.2 | 12.6 | 12.5 | 11.7 | ||||||||||||||||

| Trolley Travelling Speed | 36.7 | 36.2 | 37 | 37.5 | ||||||||||||||||||

| Crane Travelling Speed | 101.4 | 89 | 87.3 | 87.3 | ||||||||||||||||||

| Max. Wheel Load (Kn) | 175 | 190 | 203 | 215 | 230 | 215 | 228 | 240 | 249 | 259 | 305 | 322 | 332 | 345 | 357 | 358 | 375 | 388 | 405 | 425 | ||

| Total Power | 63 | 71 | 111.3 | 128.5 | ||||||||||||||||||

| Recommend Rail Model | 43kg/m | 43kg/m | 43kg/m | QU100 | ||||||||||||||||||

| Note : the working duty can be designed A6 or A7. | ||||||||||||||||||||||

Dafang supplies high quality overhead cranes, gantry cranes, jib cranes electric hoists and crane spare parts etc. You can fill out the form below, and we will contact you as soon as possible

Stella