Produtos

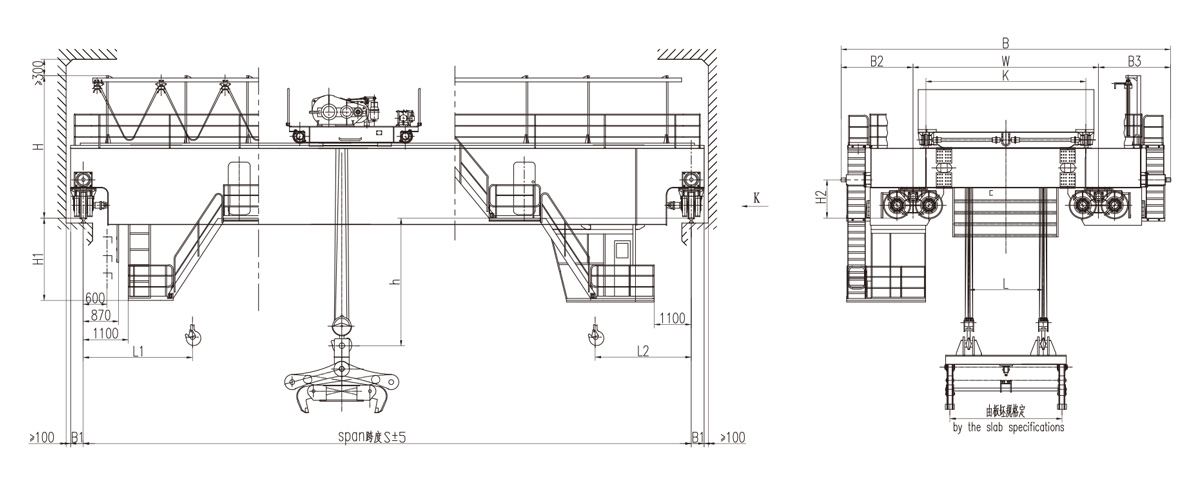

Overhead slab clamp crane is a key equipment for continuous casting and hot rolling areas of steel enterprises. It is specially used for lifting, stacking and flipping operations of high-temperature slabs. Overall structure adopts a heavy-duty box-beam bridge design. The main beam and end beam are connected to form a rigid frame by high-strength bolts, which can withstand high-temperature radiation and heavy-load shocks. The main beam usually adopts a rail-shaped box-shaped beam structure, with reinforcement plates installed inside to improve torsional resistance.

The core component is a special slab clamp device, made of heat-resistant alloy steel, and the jaws are inlaid with special ceramic fiber linings to resist high temperature burning. Clamps are automatically clamped through a lever mechanism or hydraulic system, and the mechanical self-locking design ensures that the clamping force can be maintained even in the event of power outage. The upper part of the clamp is connected to a lifting system composed of high-temperature resistant steel wire rope and balance beam. For occasions where flip operations are required, a rotating mechanism can be added to the clamp to achieve accurate flip of the slab 90 degrees or 180 degrees.

Considering the high-temperature operating environment, thermal insulation protective covers are installed in key electrical components. And the main steel structures are coated with heat-resistant and anti-corrosion coatings to ensure that the equipment operates for a long time and reliably under high temperature conditions of 400-1200℃. This specialized structural design makes the slab clamp crane an indispensable and important equipment for the continuous casting and hot rolling production lines of modern steel enterprises.

Overhead slab clamp crane is a key logistics equipment in the steel and metallurgy industry, and is mainly used in the core production links such as the transfer, stacking and process processing of high-temperature slabs. Its typical application scenarios are concentrated in the three core areas of steel production:

Continuous casting workshop: this type of bridge crane undertakes the important transfer task from the continuous casting machine's blank roll to the slab buffer area. It requires precisely grasping of high-temperature continuous cast slabs of 600-1200°C, lifting them to the slab cooling zone or directly transporting them to the hot rolling workshop.

Hot rolling plant raw material span: the slab clamp crane mainly completes the stacking management and loading operations of the slab warehouse. Here, different specifications of slabs need to be processed, and it adapts to different thicknesses and widths of slabs through adjustable clamping devices. The clamp with rotation function can flip the slab by 180 degrees, meeting the requirements of the hot rolling mill for the direction of the furnace.

Slab finishing area: for surface inspection, grinding and finished product stacking processes of slabs. The working ambient temperature here is relatively low, but the positioning accuracy is higher, and accurate positioning within ±3mm is required. In addition, in the thick plate production lines of some steel enterprises, this type of bridge crane also undertakes the key task of transporting slabs from heating furnaces to rolling mills, and puts forward extremely high requirements for the reliability and stability of the equipment.

| Capacidade de elevação | T | 35 | 50 | 65 | |

| Span | m | 27.5 | 37 | 35.5 | |

| Altura de elevação | 12 | 12 | 12 | ||

| Working Grade | A7 | ||||

Velocidade | Hositing | m/min | 0.95~9.5 | 0.95~9.5 | 0.78~78 |

| Crab travelling | 3.8~38 | 3.8~38 | 3.8~38 | ||

| trolley travelling | 8.5~85 | 8~80 | 7.5~75 | ||

| Main dimensions | H | mm | 4450 | 4850 | 4650 |

| H1 | 2650 | 2800 | 2700 | ||

| H2 | 1200 | 1200 | 1200 | ||

| B | 10900 | 10900 | 11400 | ||

| K | 5000 | 5000 | 5500 | ||

| W | 6000 | 6000 | 6500 | ||

| B1 | 400 | 400 | 400 | ||

| B2 | 2450 | 2450 | 2450 | ||

| B3 | 2450 | 2450 | 2450 | ||

| Max.Wheel Load | kN | 382 | 494 | 473 | |

| Carril de guindaste recomendado | QU120 | ||||

| Fonte de alimentação | 3-Phase A.C.50Hz 380V | ||||

A Dafang fornece pontes rolantes, pórticos, gruas, guindastes eléctricos e peças sobressalentes para gruas de alta qualidade, etc. Pode preencher o formulário abaixo e entraremos em contacto consigo o mais rapidamente possível

Stella